Introduction

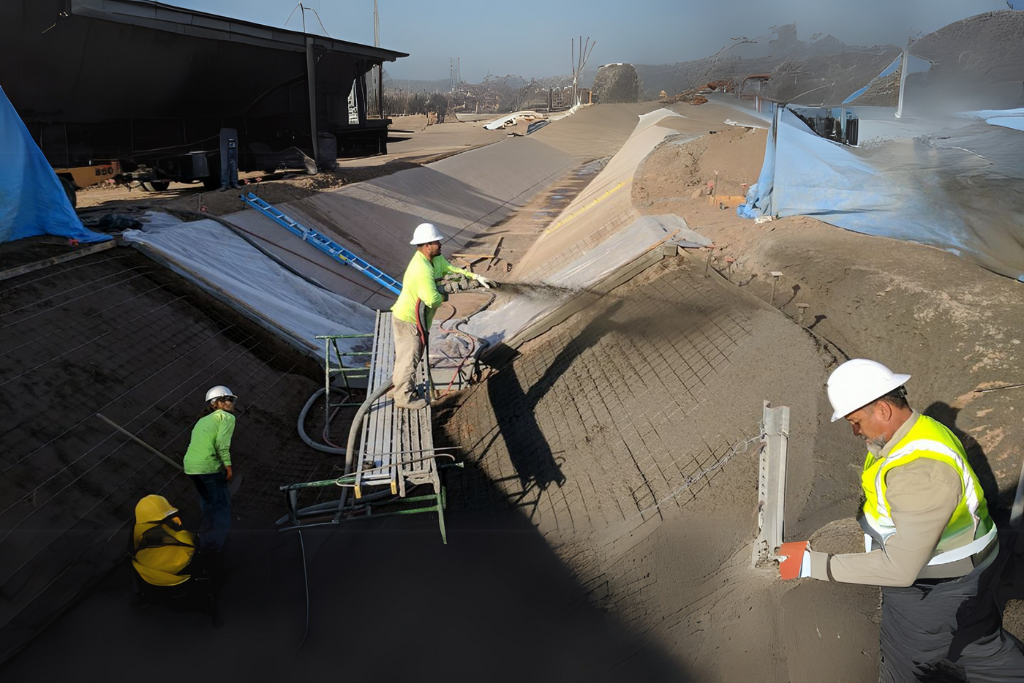

Shotcrete has become a cornerstone of modern construction and infrastructure repair—valued for its speed, versatility, and strength. From underground tunnels and retaining walls to swimming pools and slope stabilization, shotcrete offers a flexible solution for complex building scenarios. But when it comes to application, one key question often arises: Should you use wet mix or dry mix shotcrete?

Both methods involve spraying concrete at high velocity onto a surface, but they differ significantly in terms of how the material is prepared and applied. The decision between wet and dry mix shotcrete isn’t just about preference—it affects the quality, efficiency, cost, and long-term durability of your project.

Choosing the right technique depends on a variety of factors, including project size, site conditions, access, environmental constraints, and the skill level of your crew. This blog breaks down both methods—explaining how they work, when to use each one, and the pros and cons of both.

Whether you’re a contractor, engineer, or project manager, understanding these techniques will help you make informed decisions, minimize waste, and ensure top-tier results on any shotcrete job.

1. What Is Shotcrete, and Why Does the Application Method Matter?

Shotcrete is a form of concrete that is projected at high velocity through a hose onto a surface. Unlike traditional cast-in-place concrete, shotcrete doesn’t require formwork and can adhere to vertical and overhead surfaces with ease.

There are two primary techniques:

- Wet Mix Shotcrete

- Dry Mix Shotcrete (also known as Gunite)

While both deliver high-strength, durable finishes, they differ in how the concrete mix is handled, mixed, and applied—which can dramatically influence project performance and efficiency.

Understanding the distinction is essential for:

- Achieving optimal bond strength

- Minimizing rebound and waste

- Choosing the right equipment and crew

- Planning for environmental or logistical challenges

2. Wet Mix Shotcrete: Overview and Process

What is Wet Mix Shotcrete?

In wet mix shotcrete, all materials—cement, aggregate, water, and admixtures—are fully mixed before entering the delivery hose. The mix is then pumped to the nozzle, where compressed air propels it onto the receiving surface.

Application Process:

- Concrete is batched and mixed, usually in a ready-mix truck or onsite mixer.

- The wet concrete is pumped through a hose to the nozzle.

- At the nozzle, compressed air accelerates the material toward the surface.

- The nozzle operator controls spray angle and distance to ensure compaction and consistency.

Ideal For:

- Large-scale or high-volume projects

- Projects requiring low dust levels

- Enclosed environments like tunnels or tanks

- Applications where precise water/cement ratio control is essential

3. Dry Mix Shotcrete: Overview and Process

What is Dry Mix Shotcrete (Gunite)?

In dry mix shotcrete, only the dry ingredients—cement and aggregate—are pre-mixed. Water is added at the nozzle just before application, allowing the operator to control the mix’s consistency on the fly.

Application Process:

- Dry materials are loaded into a hopper and conveyed via compressed air through the hose.

- At the nozzle, water is injected into the stream.

- The operator adjusts water content in real-time, applying the hydrated mix onto the surface.

Ideal For:

- Smaller repair jobs or precision work

- Remote or hard-to-access locations

- Projects requiring maximum control over moisture content

- Jobs where mix waste must be minimized

4. Key Differences: Wet Mix vs. Dry Mix

| Feature | Wet Mix Shotcrete | Dry Mix Shotcrete |

| Mixing | Fully mixed before application | Mixed at the nozzle |

| Water Control | Fixed water-cement ratio | Adjustable at nozzle |

| Rebound (waste) | Lower | Higher |

| Dust Production | Low | High (use PPE) |

| Compressive Strength | Generally higher with additives | Slightly lower, but still strong |

| Production Speed | Faster for large volumes | Slower, more manual |

| Equipment | Requires pump and mixer | Requires gunite machine and air compressor |

| Ideal Projects | Tunnels, pools, retaining walls | Repairs, overhead work, small-scale jobs |

5. Pros and Cons of Each Method

Wet Mix Shotcrete – Pros

✅ Better consistency and quality control

✅ Lower rebound and waste

✅ Less dust (safer in confined spaces)

✅ More efficient for large volumes

✅ Suitable for fiber-reinforced mixes

Wet Mix Shotcrete – Cons

❌ More equipment required

❌ Less control over mix during application

❌ Potential issues with hose clogging

❌ Limited working time—must use before it sets

Dry Mix Shotcrete – Pros

✅ Flexible water control at the nozzle

✅ Longer material shelf life during application

✅ Lightweight equipment setup

✅ Ideal for spot repairs and vertical/overhead work

Dry Mix Shotcrete – Cons

❌ Higher rebound and dust production

❌ Operator-dependent quality

❌ Not ideal for thick layers or large pours

❌ Inconsistent finish if not applied properly

6. Choosing the Right Method for Your Project

When deciding between wet and dry mix shotcrete, consider the following:

✅ Project Size & Scope

- Use wet mix for large-scale jobs where speed and consistency matter.

- Use dry mix for smaller jobs or spot repairs requiring precision.

✅ Access & Environment

- In confined spaces or indoor areas, wet mix is safer due to reduced dust.

- Dry mix is better for remote locations where water access is limited.

✅ Crew Expertise

- Wet mix requires skilled nozzle operators and a team familiar with pumping systems.

- Dry mix demands an operator with excellent control over nozzle technique and water adjustment.

✅ Budget & Equipment

- Wet mix may incur higher upfront equipment costs.

- Dry mix offers simpler, more portable equipment but can lead to more material loss from rebound.

7. Best Practices for Both Application Methods

Regardless of the method, ensure the following:

- Surface Preparation: Clean, roughen, and dampen the substrate to enhance bonding.

- Nozzle Technique: Maintain a 90° angle and consistent distance for proper compaction.

- Layering: Apply in thin layers to avoid sagging and ensure proper set.

- Curing: Keep the shotcrete moist after application to prevent cracking and shrinkage.

- Safety: Always wear protective gear—especially during dry mix applications due to airborne particles.

Conclusion:

Understanding the difference between wet mix and dry mix shotcrete can significantly impact your project’s success. Each method offers unique benefits tailored to specific job requirements, environmental conditions, and logistical constraints. Wet mix shotcrete delivers high consistency and speed for large, enclosed, or reinforced applications, while dry mix shines in repair work, vertical surfaces, and situations demanding on-the-spot adjustments.

Choosing the right technique ensures that your shotcrete application is not only structurally sound but also efficient, safe, and cost-effective. With the right knowledge, equipment, and crew, either method can deliver long-lasting, high-quality results in everything from tunnels and bridges to dams and decorative facades.

FAQs:

- Which is stronger—wet mix or dry mix shotcrete?

Both are strong, but wet mix tends to achieve higher compressive strength due to better mix control and compaction. - Is dry mix shotcrete outdated?

Not at all! It’s still widely used for repairs, vertical or overhead work, and remote access projects. - Can I use fibers in both shotcrete methods?

Yes, though fiber integration is more common and effective in wet mix applications due to better dispersion in the mix. - Is shotcrete waterproof?

Shotcrete can be made waterproof with proper mix design, including admixtures like silica fume or waterproofing agents. - How do I reduce rebound when using shotcrete?

Ensure skilled nozzle operation, use the correct mix design, and apply in thin, controlled layers—especially critical with dry mix.